ARTICLE

Importance of soil compaction in construction

Lisa Ramoutar is a TTCA Board Director and the Laboratory Manager at Caribbean Industrial Research Institute (CARIRI). Mrs. Ramoutar is a Civil Engineer with over 10 years experience in investigating materials in construction. She supervises an experienced and knowledgeable team at CARIRI. Their goal is to improve quality in construction.

Inevitably on most construction sites you would likely find several pieces of heavy equipment undertaking a myriad of jobs, one in particular being compaction of soils or aggregates. But why, you may ask yourself is this task being undertaken and of what significance is it to the project? For the purpose of this article “soil” is used to refer to what we traditionally refer to as soil in construction as well as aggregates and crushed rocks that are used in construction.

Take a handful of soil and you may observe different particle sizes and shapes which can range from round or angular pebble sized particles that fit in the palm of your hand down to sand and even smaller silt sized particles. In its natural state these soils exist with voids between them.

When we use the soil in construction, whether for creating the foundation of a building or a roadway, or for backfilling an excavation or a retaining wall, it is critically important that the soil is properly compacted to function correctly.

Refer to your typical specification document for your project or the code that the construction is being built to and you should find requirements for compaction of the soil as being x % of the standard or modified Proctor value.

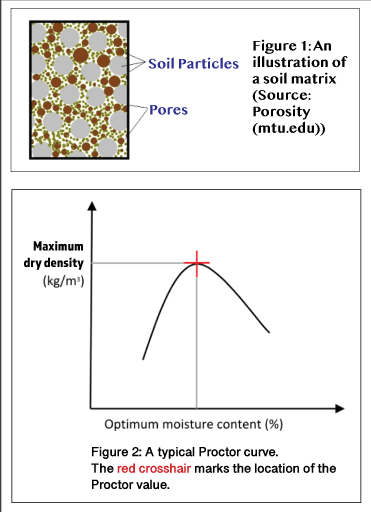

The Proctor value is the maximum dry density of the soil along with the optimum moisture content required to achieve this value as determined from laboratory testing. By systematically increasing the moisture content of the soil under controlled lab compaction and assessing its density we are able to obtain this value. The Proctor value varies for different materials and for different sizes of materials. For example a clay type soil which has very small particles will have a different Proctor value than a limestone crusher run. Basically if you start with a dry sample of soil, of known mass and add moisture to it, the soil will tend to bind together when mixed with water and compacted, that is unless the soil is free-draining. As you increase the moisture, the soil particles are expected to bind closer together to compact further. However we reach a point of maximum density whereby the further addition of water, instead of binding the particles, serves to do the opposite and actually decreases the density. When plotted on a graph of density vs. moisture content we get the Proctor curve for the soil. See Figure 2 for an example of a Proctor curve of a soil.

Once the soil is compacted on site, using rollers, rammers or compactors an assessment is made of the in-situ density. This can be done in via field density testing using a density tester or the sand cone test. The compaction obtained on site is compared with the Proctor value of that soil and the percent compaction attained in the field is calculated to check for compliance with the project specifications, the x %.

But, back to the importance of compaction in construction. There are three main reasons to ensure proper soil compaction in construction:

1. To improve bearing capacity and shear strength which ultimately lends to stability. Compaction increases the overall friction from the interlocking of particles and creates a denser more stable material for withstanding forces both vertically and laterally. Inadequate compaction allows for movement of the loose material during service loading.

2. To reduce water permeability. As the soil normally exists with voids between the particles, the interconnectivity of these voids increases the permeability of the soil and allows a pathway for water once infiltrated to flow through, carrying with it the smaller, lighter soil particles. This removal of fines from the soil matrix leaves the coarser particles alone in place to withstand the loading and can result in settlement, shifting and ultimately failure in service. Consider for instance insufficient compaction of backfill for a retaining wall. During a rainfall event the permeability leads to a build-up of water at the soil-wall interface. This increases the pressure on the retaining wall which can lead to overturning of the retaining wall. Alternatively consider a roadway where water enters the aggregate layers below the asphalt and the fine materials are lost through the structure; this leaves the roadway susceptible to failure as it is no longer able to adequately support traffic loads.

3. To reduce settlement. Consider again a roadway insufficiently compacted, once opened to vehicular traffic the service loads are transferred from the asphalt layer to the underlying aggregate and soil layers. This load will cause the particles to move and compact within the void spaces, to the detriment of the asphalt layer. Especially with road construction where the soil forms the foundation, insufficient compaction leads to settlements which can lead to failure. Compaction reduces the voids and therefore reduces the chance of settlement.

In more temperate climates, there are other factors to consider such as the freezing and thawing of water in the void spaces, but those are not addressed in this article.

Overall, the benefits of ensuring proper compaction during the construction phase to ensure stability and durability far outweigh the costs and other consequences associated with remedial work and replacement after the construction is complete and in use.